Low voltage motors are ubiquitous in modern industry, powering everything from small machinery to large-scale manufacturing equipment. With their widespread use comes the necessity for regular maintenance and repairs to ensure optimal performance and longevity. Proper low voltage motor repairs are crucial to prevent equipment failures, reduce downtime, and maintain production efficiency. In this article, we will delve into the importance of proper low voltage motor repairs and explore the consequences of neglecting them.

The Consequences of Neglecting Low Voltage Motor Repairs

Low voltage motors are designed to operate within a specific voltage range, typically below 600 volts. While they may seem less critical than their high-voltage counterparts, neglecting repairs can have serious consequences, including:

Equipment failure: Motor failure can lead to unplanned downtime, resulting in production losses, missed deadlines, and revenue impact.

Safety risks: A faulty motor can cause electrical shock, electrocution, or even fires, posing serious risks to personnel and equipment.

Energy efficiency: Inefficient motor operation can lead to increased energy consumption, boosting energy bills, and contributing to greenhouse gas emissions.

Reduced product quality: Motor malfunction can affect product quality, leading to rejects, rework, or scrap, which can damage a company’s reputation and bottom line.

Identifying Common Issues in Low Voltage Motors

To perform proper repairs, it’s essential to identify common issues affecting low voltage motors. Some common problems include:

Worn bearings: Worn or failing bearings can cause vibration, increased motor temperature, and reduced efficiency.

Electrical connections: Poor or corroded electrical connections can lead to motor overheating, reduced torque, or complete failure.

Brush wear: In DC motors, worn or damaged brushes can cause reduced efficiency, increased sparking, or motor stall.

Winding faults: Insulation breakdown, short circuits, or open circuits in the motor windings can cause reduced performance, overheating, or motor failure.

Types of Low Voltage Motor Repairs

Low voltage motor repairs can be classified into three main categories:

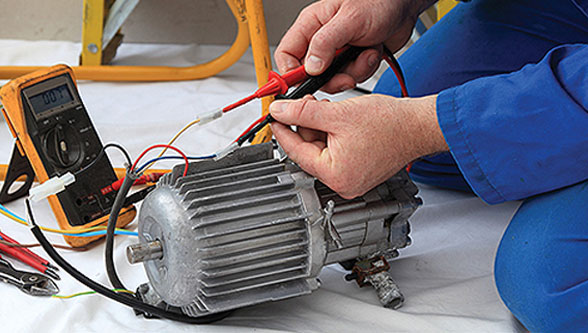

Inspection and maintenance: Regular inspections to identify potential issues, clean the motor, and perform minor adjustments.

Routine repairs: Replacing worn parts, such as bearings or brushes, and re-soldering electrical connections.

Major overhauls: Complete motor disassembly, replacing major components, and rewinding motor windings.

Importance of Training and Qualifications for Repair Technicians

Properly trained and qualified repair technicians are crucial to ensuring that low voltage motor repairs are performed correctly and efficiently. They should possess:

Theoretical knowledge: Understanding of electrical theory, circuit analysis, and motor operation principles.

Practical skills: Hands-on experience with motor repair, troubleshooting, and maintenance.

Industry certifications: Relevant certifications, such as those from the Electrical Apparatus Service Association (EASA) or the International Electrotechnical Commission (IEC), demonstrate expertise and adherence to industry standards.

Best Practices for Low Voltage Motor Repairs

Adhering to best practices ensures that repairs are performed efficiently, effectively, and safely. Some key best practices include:

Follow manufacturer guidelines: Consulting the manufacturer’s instructions and recommendations ensures that repairs are performed correctly.

Use proper tools and materials: Using the correct tools and materials minimizes the risk of damage or safety hazards.

Perform thorough diagnostics: Identifying the root cause of the issue ensures that the correct repair is performed, reducing the risk of recurrent failures.

Document repairs: Accurate record-keeping helps track maintenance history, enables trend analysis, and facilitates future repairs.

Selecting the Right Repair Shop

Choosing the right repair shop or service provider is critical to ensuring that low voltage motor repairs are performed correctly. Look for:

Experience: A proven track record of successful motor repairs and satisfied customers.

Certifications: Industry-recognized certifications demonstrate expertise and adherence to industry standards.

Equipment and facilities: Modern facilities and specialized equipment ensure that repairs are performed efficiently and effectively.

Warranty and support: A comprehensive warranty and dedicated customer support provide peace of mind and minimize downtime.

Cost-Benefit Analysis of Proper Low Voltage Motor Repairs

While investing in proper low voltage motor repairs may seem costly, the benefits far outweigh the expenses. Consider:

Increased uptime: Reduced downtime ensures that production continues uninterrupted, minimizing lost revenue and opportunities.

Extended motor life: Proper repairs prolong motor life, delaying the need for premature replacement.

Energy savings: Efficient motor operation reduces energy consumption, leading to cost savings and environmental benefits.

Improved safety: Reduced risk of electrical accidents and fires protects personnel and equipment, minimizing potential liabilities.

Conclusion

Proper low voltage motor repairs are crucial to maintaining production efficiency, reducing downtime, and ensuring safety. By identifying common issues, understanding the types of repairs required, and following best practices, companies can prevent equipment failures, reduce energy consumption, and improve product quality. Remember, investing in proper repairs is a cost-effective decision that pays dividends in the long run.

Frequently Asked Questions

What is the typical voltage range for low voltage motors?

Low voltage motors typically operate within a voltage range of less than 600 volts.

What is the most common cause of low voltage motor failure?

The most common cause of low voltage motor failure is worn bearings, accounting for approximately 40% of all motor failures.

How often should I perform maintenance on my low voltage motors?

The frequency of maintenance depends on factors such as operating conditions, motor design, and industry recommendations. As a general guideline, perform maintenance every 6-12 months, or as specified by the manufacturer.

What is the benefit of using a certified motor repair shop?

Using a certified motor repair shop ensures that repairs are performed to industry standards, minimizing the risk of subpar workmanship, and providing assurance of a quality repair.

What is the average cost of a low voltage motor repair?

The cost of a low voltage motor repair varies depending on the type of repair, complexity, and motor size. On average, a minor repair can cost between $100-$500, while a major overhaul can cost between $1,000-$5,000 or more.